(TWS stands for Ten Week Special)

TWS was a loco born out of neccessity- ten weeks before the 2009 convention in Perth, and after everything had been booked and paid for, I discovered that the Castledare track had only 900m of 5-inch track out of a total of over 5Km. I didn't want to go all that way for such a small (relatively) track, so the idea of a 7 1/4 loco was hatched.

I had a great deal of assistance from Peter Lawson (Evandale club), who supplied wheel blanks, petrol motor, and pre-bent chassis rails. He also made the riding car for me, as there was just not enough time for me to be able to do this.

I already had a 24 volt 55 amp alternator so a pair of 300w 24v motors from Oatley Electronics rounded out the major bits. After a fair bit of midnight oil burning, I had the bulk of the loco done in 5 weeks, leaving 5 more weeks for final sorting.

One problem I had was exactly how to control the alternator. After asking questions around the place, including on the COALS mailing list, it seemed no-one could answer the question of how much current at what voltage was required to drive the alternator to full output and whether the field windings should be current or voltage fed.

In the end, I fitted the instrumentation shown in the picture of TWS's control panel (the top row is current, the bottom is voltage). This gave me the numbers I wanted- the alternator can be driven to 30 amps at 30 volts with just 10 volts at 2 amps into the field winding. With the addition of a couple of steering diodes, the alternator can easily be driven to maximum output and much more.

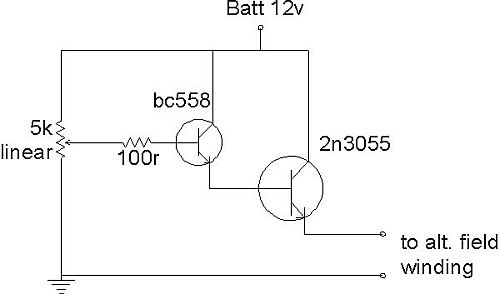

Graham Reardon (Evandale club) supplied me with the circuit he has been using for some time to control the field winding on his petrol-electric loco, this has proven to be excellent, giving smooth reliable control of the loco. He has kindly allowed me to put the circuit here for all to use. The '3055 needs a heat-sink, but otherwise the construction is not critical.

My second version of Grahams' circuit is essentially identical, but uses a BDX53C darlington transistor I had to hand, to reduce the component count and the number of tracks on the board. However, a BD649 (still an NPN darlington) will do just as well and Jaycar carry them (ZT2198). I also added a small ttl relay (Jaycar SY4030) from the base of the transistor to ground, operated by the riding car brake (via a pic 12F683), to cut the current to the motors while braking. The pic monitors the voltage from the wiper of the pot and will not allow the relay to release until the control voltage has been reduced to (almost) zero. No nasty surprises when you let the brake off!

When time permits, I will redraw the circuit and add the pcb layout I used, but in the meantime, if anyone is interested in the pic version of the controller, drop me an email to bats059 [at] gmail [dot] com and I will see what I can do.

I also added a Stebel air-horn to the loco, a GPNTC-12-BLACK, available from on-line auto parts in Queensland. I have to say I was very impressed both by the horn, and by the speed of their service- it was in my mail-box the very next day when I ordered it on-line. I have since ordered more bits from them, with the same result each time- don't you wish all companies could do that!

Here is a spreadsheet (loco weights.xls) I developed to calculate the weight of a loco, just enter the sizes (in mm) of the bits of steel you are using and it will give you a total weight. I have checked it against several commercial on-line calculators and it agrees reasonably well with them, it seems to depend on exactly what factor they have used for the weight of steel per unit volume. I took my figure from a booklet by MetalLand, they use the figure of 7.850 Kg/cu M. There is also an area for holes, so it will deduct the weight removed by things like windows, etc.

I have left some data from my new diesel-hydraulic loco in there to give an idea of what is required. Data entry is in the white areas, the yellow areas are text labels and the blue areas are where the calculations are done.

Here is another spreadsheet (Gear Cutting calcs.ods) I developed to do the calculations for gearcutting. Just enter your data in the green cells, it will work out the rest. There is a section near the bottom to convert dp to module and vice-versa. The results are given on the right hand side of the sheet, in imperial and metric.

The spreadsheet is done in Libre office, I have converted it to excel(Gear Cutting calcs.xls) but I have no way of testing whether the excel version works or not. If you see any errors or problems, please email me at [bats059 {at} gmail {dot} com] after removing the anti-spam stuff first.

Number of visitors to this page so far: